OUR MACHINE SAFETY SERVICES

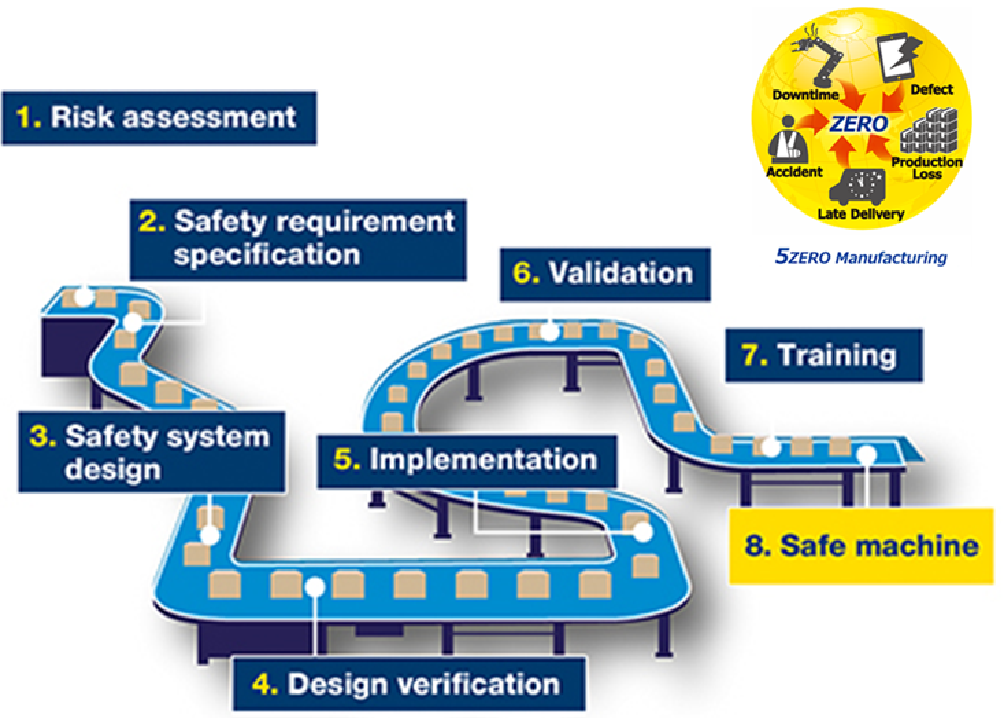

Machinery Safety Life Cycle

Everyone deserves a safe work environment. And every employer is obligated to provide it. But machine safety is a lot more than just a moral and legal requirement. It can also make your workplace more productive and cost effective.

Our TUV-certified safety engineer can tailor a machine safety system specific to your unique setup. One that’s fully compliant, easy to maintain and comes complete with official validation documentation for future safety audits. We can also provide standard, operating procedures, safety training and lockout/tagout services.

1. Risk Assessment

Based on International standards, risk reduction starts with the Risk Assessment; SafeLogix offers a task-based risk assessment in collaboration with your team who work on the machinery. Once the risk assessment is finished you are provided with a report including identified hazards and recommendations for risk mitigation.

2. Safety Requirement Specification

Once the risk has been assessed a Safety Requirement Specification (SRS) will be developed which contains all the requirements of safety functions to be performed by the safety related control system. The SRS lays out the foundation for the safety system design and is used as a reference during the implementation and validation.

3. Safety System Design

Once the Safety Requirements Specification is prepared, SafeLogix can work with your team or with one of our approved safety system integration partners to design a solution that will comply with all relevant Australian standards.

4. Design Verification

The designed safety system has to be verified to ensure the compliance with the Safety Requirement Specification. The verification is done by review and analysis (Validation by Analysis). In general, analysis is necessary to verify that the reduction in risk has been achieved.

5. Implementation

Our certified safety engineers can work with your team or with one of SafeLogix’s approved safety system integration partners with the installation and commissioning to ensure the safety system is installed correctly.

6. Validation

When the installation and commissioning of the safety system is finished a validation by test has to be carried out to ensure that the implemented safety system complies with the Safety Requirements Specification. The machine safety functions are tested and validated that they meet the required category/PL/SIL. A validation document is prepared for future audits.

7. Training

Training is necessary to enable the operation and maintenance personnel working on the machinery with the newly integrated safety control system. SafeLogix can provide training courses for all the personnel working on the machinery with the new safety control system.